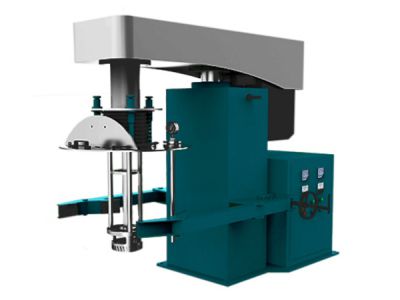

Horizontal Turbine Bead Mill, RTSM-400CJD

This horizontal turbine bead mill features turbine-driven rotor and static self-cleaning screen. When the grinding machine runs at high speed, the turbine rotor inside will disperse the material inside instantly, with the large particles ground in the faster-grinding chamber. Under the centrifugal force, the large particles will be ground repeatedly and later be wrapped up by unground particles, which will avoid the agglomeration of particles. After the whole process has been finished, the ground particles will be moved to the new part. During the operation, the materials will be effectively ground.

Features

- The grinding chamber is divided into three areas with different grinding speed, which will deliver extraordinary grinding performance;

- Special spiral rotor structure, gentle bead operation and stable performance, no harm caused to materials like carbon nanotubes;

- Certified mechanical seal, long service life. Solvent can be used as sealing medium for mechanical seal, avoiding pollution even when there is leakage;

- Formula can be easily imported and exported with only pressing the button;

- Reasonable design of the discharge unit, self-cleaning screen is enabled to deliver long screen service life.

Application

New energy, conductive agent, lithium iron phosphate(LFP/LiFePO4), paint, coating, pigment etc.

Specifications

- Model No. RTSM-400CJD

- Volume: 400L

- Power: 315kW

- Materials of Inner Grinding Chamber Component: Silicone Carbide

- Materials of Outer Grinding Chamber Component: SS304 Stainless Steel

- Grinding Principle: Turbine Drive Type

- Materials of Rotor Component: Ceramic

- Max. Line Speed: 15m per second

- Screen Component Structure: Disc Type

- Operation Method: PLC with Touch Screen

- Mechanical Seal Component Style: Double-end Container Type

- Pneumatic Diaphragm Pump: 3-inch Pneumatic Diaphragm Pump