Bead Mills

Root offers high-efficiency bead mills, dispersers, mixers and emulsifiers for industries like fine chemical engineering and new materials. Bead mills are designed for particle-grinding processes, various types are offered, including agitator bead mills, laboratory agitator bead mills, basket mills and three roller mills, to satisfy the requirements of both industrial productions and lab experiments.

RTSM series industrial agitator bead mills are specially designed for mass productions, applying the optimal combination of wet-milling technology and horizontal structure.

-

- Disc Agitator Bead Mill (Static Sieve)RTSM-AJ series disc agitator bead mill with static sieve is designed for industrial mass productions of water-based, oil-based materials and other materials with low viscosity. With centrifugal force driven product outlet filtered by static sieve, larger outlet rate is allowed, and larger production capacity can thus be achieved. View More

-

- Pin Type Agitator Bead Mill (Static Sieve)RTSM-BJ series pin type agitator bead mill with static sieve is a novel type designed according to actual production situations, modified from traditional pin type agitator bead mill and granted nanoscale grinding fineness. View More

-

- Turbine Agitator Bead MillRTSM-CJ series turbine agitator bead mill with static sieve is designed with high grinding power and nanoscale grinding fineness. High grinding and energy efficiency; doubled grinding efficiency compared with traditional bead mills with disc agitators. View More

-

- Disc Agitator Bead Mill (Dynamic Gap Separator)RTSM-AD series disc agitator bead mill with dynamic gap separator is designed for grinding and dispersion of medium/high solid content, medium/high viscosity materials. Disc agitator offers the ability of handling various materials and various particle fineness. View More

-

- Pin Type Agitator Bead Mill (Dynamic Gap Separator)RTSM-BD series pin type agitator bead mill with dynamic gap separator is designed for micron/sub-micron/nano-scale grinding. Outlet separator with dynamic/static gap offers the ability of handling medium/high viscosity materials. View More

-

- RTSM series laboratory agitator bead mill is specially designed for small-lot productions and formula researches and other lab uses. With precise and reliable mechanical seal, good stability and durability are granted. Grinding chamber is totally sealed, external air is blocked from getting inside to produce bubbles, and internal material is blocked from getting outside to produce pollutions. View More

-

- RTLM series industrial basket mill does fine grinding and dispersing works in a single process. Basket mill satisfies requirements of high grinding fineness, does good jobs in productions of paint, pesticide, ink, etc., and its cleaning work is also easy and convenient. Utility and cost-effective. View More

-

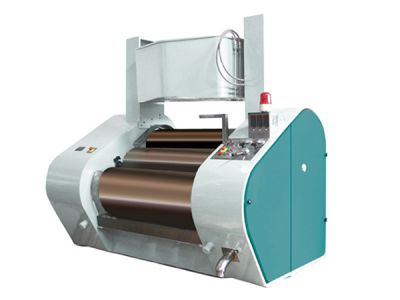

- Three roller mill performs a high grinding fineness among all wet grinding devices, and is qualified for handling materials with high-viscosity and ultra-fine particles. The suitable application is medium/high viscosity material particle refining in industries such as paint, ink, pigment, plastic, etc. View More

If you are looking for solutions or equipment to build or upgrade your fine chemical, nano material, biomedical, etc. factory or laboratory, here is the right place. Root is a professional provider of equipment, solution and services. We offer a complete series of equipment for grinding, dispersing, mixing and emulsifying, no matter industrial or experiment, we have a good choice for you. If you’d like to build up a new factory or production line, check out our solutions and EPC services. Communicate with our excellent engineers, tell us what you need, let’s create the best solution, and keep everything under control with our EPC services. We also offer premium customer services, to make sure your device is always in perfect condition.