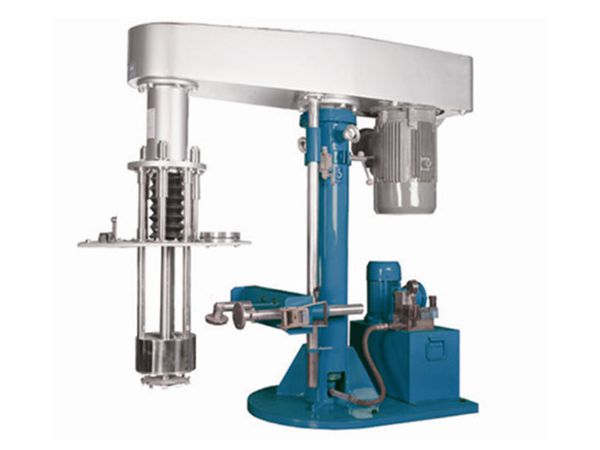

Industrial Basket Mill, RTLM Series

RTLM series industrial basket mill does fine grinding and dispersing works in a single process. The basket mill equips a milling basket filled with beads and a millbase container, during its process, the basket is lowered into the millbase, an impeller pumping wheel agitates the beads and circulates the millbase through the basket, the millbase is thus grinded and dispersed during this circulation. Basket mill satisfies requirements of high grinding fineness, does good jobs in productions of paint, pesticide, ink, etc., and its cleaning work is also easy and convenient. Utility and cost-effective.

Features

- Suitable for pilot scale production and industrial mass production.

- Sturdy and durable structure; milling basket lowered/raised by hydraulic drive, stable and convenient.

- Fine grinding and dispersing works done in a single process, a single container by a single device.

- High efficiency, high production capacity, low cost, good grinding fineness; low material vestigital, easy for cleaning.

- Imported frequency changer, continuous-variable speed adjustment.

- Customizable for special requirements, non-standard configurations are available, such as explosion-proofness, tight-sealing, belt clamp, handscrew clamp, pneumatic clamp, etc.

- CE and ISO9001 certified.

Applications

Pilot scale production and industrial mass production.

Specifications

| Model | Power (KW) | Rotate Speed (RPM) | Maximum Lifting Distance (MM) | Grinding Capacity (MM) |

RTLM-4 | 4 | 0-1440 | 600 | 40-80 |

RTSG-5.5 | 5.5 | 0-1440 | 800 | 50-100 |

RTSG-7.5 | 7.5 | 0-1440 | 800 | 60-150 |