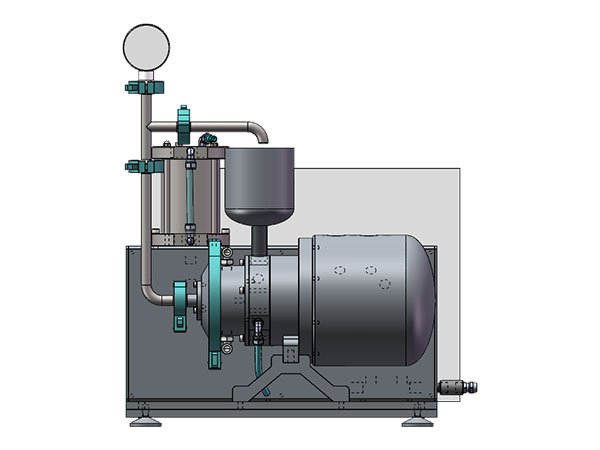

Horizontal Laboratory Disc Bead Mill, RTSM-0.5BJD

RTSM-0.5BJD disc bead mill is made based on laboratory demands of researches and small-scale experiments. It can achieve micron (1-15μm) to sub-micron (0.8-1μm) final fineness. The grinding machine is made with efficient cooling system and micron-level gap dynamic separation system, ensuring materials are smoothly discharged. In addition, the grinding chamber and rotor of this disc bead mill can be made of ceramic to enable all materials to be effectively ground. Based on all these advantages, our horizontal laboratory disc bead mill is applicable for grinding water-based coatings and paints, pesticides, pigments and dyes.

Features

- The minimum grinding media size can be as small as 0.1mm, and the products made with mature formula can be ground to nanometer level;

- High grinding efficiency, 1.5L lithium iron phosphate slurry can be ground within 30min;

- Suitable for grinding 1-6 L materials, making the bead mill an ideal choice for new product development and product sample production;

- Flexible technique application, suitable for grinding various materials, with the highest filling rate reaching 88% and the highest linear speed being 15.8m/s;

Specifications

- Model No. RTSM-0.5BJD

- Volume: 0.5L

- Power: 4kW

- Materials of Inner Chamber: Silicone Carbide

- Materials of Outer Chamber: SS304 Stainless Steel

- Grinding Principle: Pin Type

- Materials of Rotor Component: Ceramic

- Max. Line Speed: 15.8m per second

- Materials of Screen Component: SS304 Stainless Steel

- Operation Control: PLC with Touch Screen

- Mechanical Seal: Double-end Container Type

- Pneumatic Diaphragm Pump: 3-inch Pneumatic Pump Type